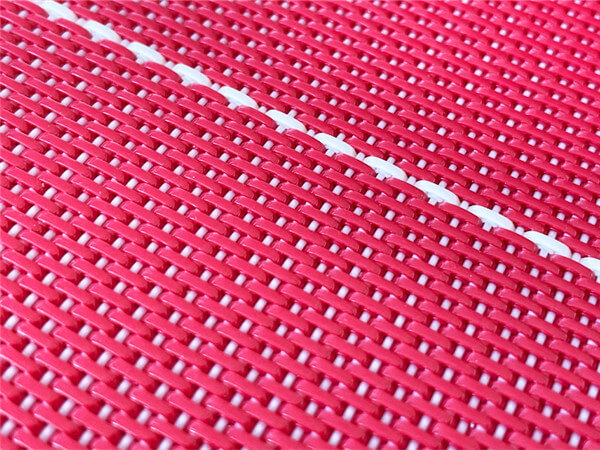

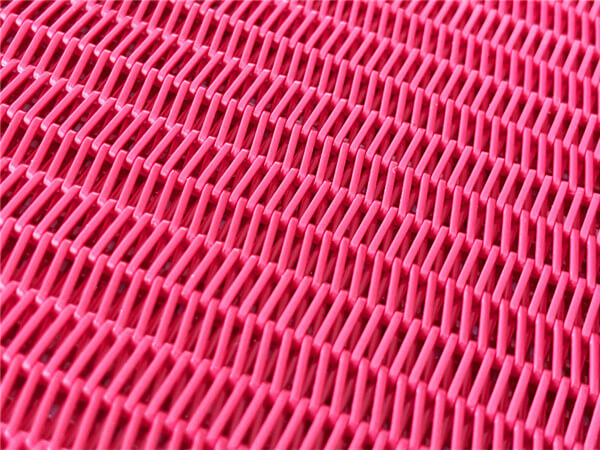

Dryer fabrics play an important role in the drying process and paper machine efficiency. PFM Screen can provide a full range of woven and spiral design dryer fabrics to adapt to the working conditions of all paper machines.

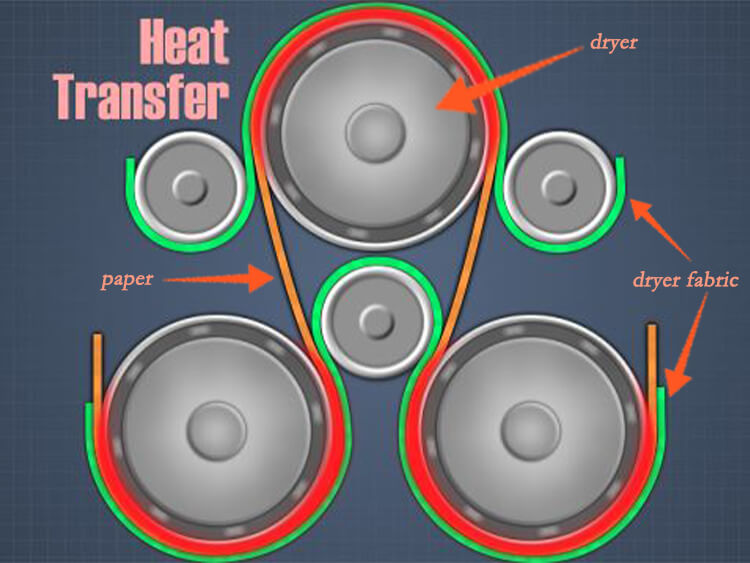

In the dryer section, the paper web passes through a closed space with the dryer fabric, and the closed space contains a plurality of steam-heated drying cylinders. Use steam to heat them to 130ºC to ensure that the paper is now 80 to 85% dry.

Subsequently, the paper will also pass through another set of heated drying cylinders along with the drying fabric, during which it will lose approximately 93% of the water.

In order to achieve better results in terms of drying efficiency, PFM Screen has developed a full range of dryer fabrics. These dryer fabrics always maintain high strength, high durability and high hydrolysis resistance throughout the life of the fabric.

The PFM Screen drying fabric adopts the best materials and special design to support fast cleaning, high heat resistance and can maintain a stable structure during high-speed movement, thereby meeting the customer's production goals.