In recent decades, the paper industry has made great progress, and the speed and width of paper machines have been continuously improved, thus greatly enhancing the production capacity. However, high speed puts forward higher requirements on the design of paper machines, especially the requirements for composite forming fabrics become more stringent.

In the paper machine clothing, the forming fabric plays the role of dewatering the pulp and forming the paper sheet. The cleanliness of the forming fabric is critical to the running state of the paper machine and the quality of the paper produced, and it is also important to maximize the life of the forming fabric.

Contaminated forming fabric

Over time, contamination build-up on your forming fabrics can have drastic effects on runnability.

Removing all impurities before the pulp enters the headbox is the best option, but it is difficult to achieve this, so the efficient cleaning of forming fabrics by various cleaning methods is very important in the papermaking process system.

Currently, the two most effective cleaning methods for forming fabrics are:

Oscillating high pressure water jet cleaning

Chemical cleaning: acid cleaning agent, alkaline cleaning agent

The oscillating high pressure water jet cleaning is the best and most widely used method of cleaning forming fabrics.

Best for guide rollers

Do not install on the tension roller

Single or composite layer forming wire installed on the opposite side (wear side) of the forming wire

Double or triple mesh installed on the front side of the forming wire (paper side)

Nozzle size [Ø]: 0.7-1.2mm, 1mm is best. Conversely, with larger diameter nozzles, water consumption will increase without a noticeable improvement in cleaning.

Nozzle Spacing: 200mm stroke for 66, 100 and 200mm spacing; 300mm stroke for 75, 150 and 300mm spacing.

Spacing between nozzle and forming fabric: 100-300mm for best cleaning effect.

Washing water pressure: suitable water pressure is 20 to 30 bar, more than 30bar may damage the forming fabric.

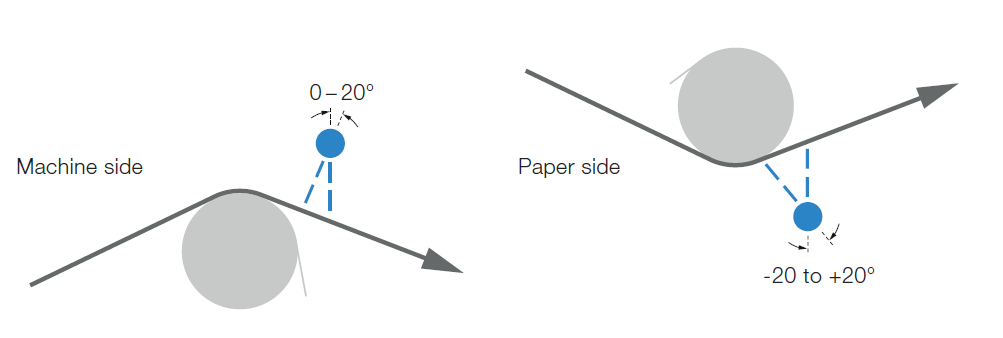

Angled at 0 – 20° with the run of the forming fabric. Angling the shower against the fabric run direction generates the highest impact energy for cleaning, but also increases misting.

Angled at 0 – 20° with the run of the forming fabric

Damaged by High Pressure Showers

R = (MS / L) x D

where

R = oscillation rate (mm/min)

S = fabric speed (m/min)

L = fabric length (m)

D = diameter of jet contacting the fabric (mm), about twice the diameter of the nozzle.

Forming fabrics are primarily made of polyester monofilaments, which are susceptible to contaminants such as asphalt and tar. Recycled paper can also contain latex, making the situation worse. In this case, chemical and mechanical cleaning can be used simultaneously.

Fast response time

No corrosive effect on polyester and polyamide materials

Easy and safe to use

Environmentally friendly

Alkaline cleaner for removing organic contaminants such as resins, rosin, organic esters, etc.

Alkaline solvent mixture that reacts faster than pure caustic products

Acid cleaner for removing inorganic contaminants such as calcium carbonate, chalk, etc.

Acidic solvent mixture with dual action to remove organic and inorganic deposits

Neutral cleaning agent, the cleaning effect is relatively limited

Shower with 1.5mm holes at a distance of 5 mm

The jet has to be orianted against an inside return roll which will distrubute the jet all over the fabric

Machine speed at its minimum

All showers closed

Fabrics containing PA Yarns are damaged by strong acid cleaning

PES Yarns are damaged by strong alkaline cleaning

Polyamide yarns are damaged acid improper cleaning