We use wires made of PET, PPS, PEEK, PA, antistatic and other materials for product production. Through intensive cooperation with various material manufacturers, our raw materials are optimally matched to our production technology as well as their possible applications.

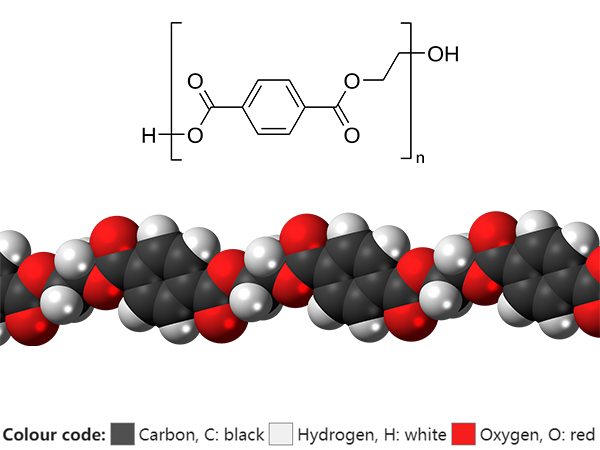

PET is a versatile and widely used thermoplastic polymer that belongs to the polyester family. It is known for its exceptional clarity, strength, and lightweight properties.

Physical state: solid

Temperature resistance: Continuous service temperature -20 °C to +150 °C

Density (specific gravity): 1.38 g/cm³

Fire class: normally flammable according to UL94 HB

very high rigidity, very high strength and hardness

excellent gliding properties (even when wet)

very good wear resistance

constantly low sliding friction, very low sliding wear

very low moisture absorption (at saturation 0.5%)

extremely low thermal expansion

very good creep resistance

excellent dimensional stability

good electrical insulation properties

good resistance to weak acids, alkalis, salt solutions, oil and fuels

physiologically harmless

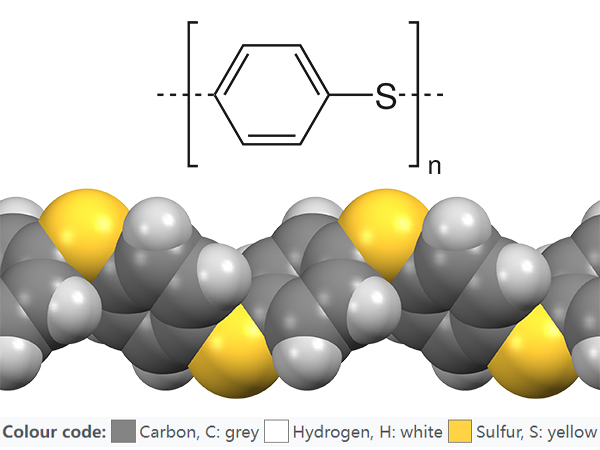

PPS is a high-performance thermoplastic polymer known for its exceptional heat resistance, chemical resistance, and mechanical properties. It is a semi-crystalline material that belongs to the family of aromatic polymers. PPS exhibits excellent dimensional stability and is often used in demanding industrial applications where high temperature and chemical resistance are required.

The connection of aromatic monomer units via sulfur atoms results in particularly resistant polymers whose good mechanical properties are retained even at temperatures well above 200 °C, so that continuous use of up to 240 °C is possible, depending on the load. Stresses at temperatures of up to 270 °C are also briefly withstood.

Mechanical Properties: PPS offers excellent mechanical strength, stiffness, and dimensional stability. It has a low coefficient of thermal expansion, meaning it experiences minimal size changes with temperature variations. PPS also has good creep resistance, fatigue resistance, and impact strength, making it suitable for demanding mechanical applications.

Physical state: solid

Density: 1.35 g/cm3

Approximate melting point: 285°C

Modulus of elasticity: 4000 MPa

Water absorption: 0.05%

Very good chemical resistance, resistant to various fuels, oils, ethanol, freon, xylene

Coefficient of thermal expansion: 0.5 10−4 K−1

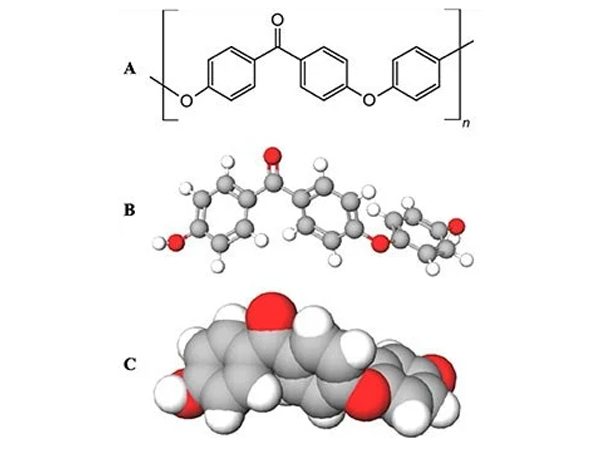

PEEK is a high-performance thermoplastic polymer known for its exceptional mechanical, thermal, and chemical properties. It belongs to the family of polyaryletherketones and is widely used in industries where extreme performance and reliability are required. PEEK offers a unique combination of high temperature resistance, excellent strength, dimensional stability, and chemical resistance.

Here are the key characteristics and details about PEEK material:

Heat Resistance: PEEK exhibits remarkable heat resistance, with a high melting point of approximately 340°C (644°F). It can withstand continuous use at high temperatures without significant loss of mechanical properties. This makes PEEK suitable for applications in demanding environments, such as aerospace, automotive, and electronics industries.

Mechanical Properties: PEEK possesses excellent mechanical properties, including high tensile strength, stiffness, and impact resistance. It maintains its mechanical performance even at elevated temperatures, allowing it to withstand demanding load-bearing applications.

Chemical Resistance: PEEK demonstrates exceptional resistance to a wide range of chemicals, including acids, bases, solvents, and hydrocarbons. It retains its integrity and mechanical properties when exposed to aggressive chemicals, making it suitable for applications in chemical processing, oil and gas, and medical industries.

Dimensional Stability: PEEK exhibits excellent dimensional stability, meaning it maintains its shape and size under various temperature and environmental conditions. It has a low coefficient of thermal expansion, ensuring minimal dimensional changes even with temperature fluctuations.

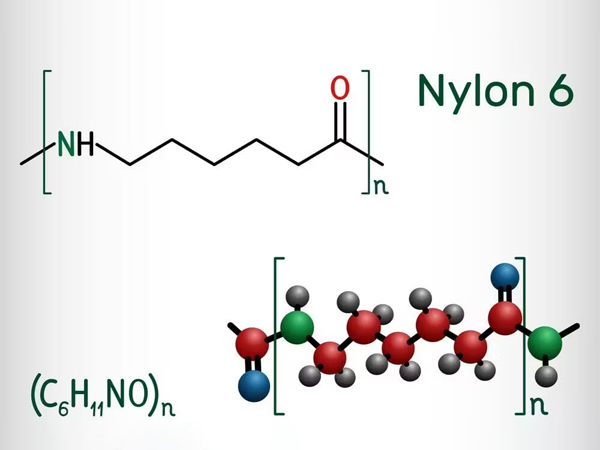

PA (Polyamide)

Here are the key characteristics and details about PA material:

Mechanical Properties: PA exhibits excellent mechanical properties, including high tensile strength, impact resistance, and toughness. It can withstand heavy loads and has good resistance to wear and abrasion. PA is often used in applications where mechanical strength and durability are required.

Chemical Resistance: PA has good resistance to many chemicals, such as oils, solvents, and alkalis. It retains its mechanical properties and integrity when exposed to various chemicals, making it suitable for applications in the automotive, chemical, and industrial sectors.

Moisture Absorption: PA has moderate moisture absorption properties. It can absorb and release moisture, which may affect its dimensional stability. Special grades of PA are available with reduced moisture absorption characteristics for specific applications.

Heat Resistance: PA has a relatively high melting point, typically around 220-260°C (428-500°F). It retains its mechanical properties at elevated temperatures and exhibits good heat resistance, making it suitable for applications requiring thermal stability.