When it comes to industrial conveyor belts, two popular choices stand out: Polyester Mesh Belts and Stainless Steel Mesh Belts. Each has its own advantages and limitations, making them suitable for different applications. In this article, we will compare these two types of mesh belts, analyze their pros and cons, and guide you on when to choose each type.

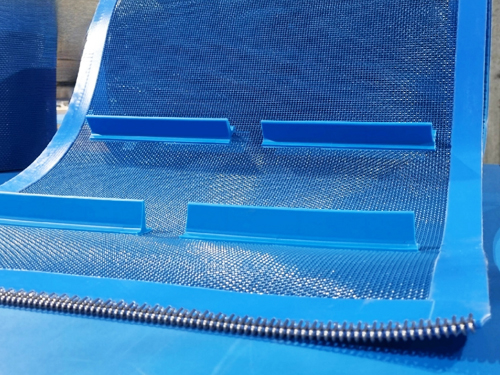

Polyester Mesh Belts

Polyester mesh belts are made from high-strength synthetic fibers. They are lightweight, flexible, and resistant to chemicals and moisture, making them ideal for applications where durability and resistance to corrosion are essential.

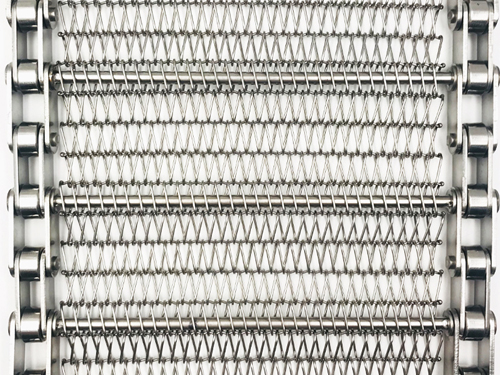

Stainless Steel Mesh Belts

Stainless steel mesh belts are made from woven or linked metal wires, providing superior strength and heat resistance. They are commonly used in high-temperature environments and heavy-duty industrial processes.

| Feature | Polyester Mesh Belts | Stainless Steel Mesh Belts |

| Material | Synthetic polyester | Stainless steel |

| Durability | High, but sensitive to high temperatures | Extremely durable, can handle heavy loads and harsh environments |

| Heat Resistance | Moderate (up to 150°C) | Very high (above 1000°C) |

| Chemical Resistance | Excellent | Good but can corrode with certain chemicals |

| Moisture Resistance | Excellent (resistant to water and humidity) | Can rust if not properly treated |

| Flexibility | High, adaptable to curved conveyor systems | Limited flexibility, better for flat surfaces |

| Weight | Lightweight, easy to handle | Heavy, requires stronger conveyor systems |

| Maintenance | Easy to clean and replace | Requires periodic maintenance and anti-corrosion treatment |

| Cost | More affordable | More expensive due to material and durability |

Pros:

- Lightweight and flexible

- Excellent resistance to moisture and chemicals

- Cost-effective solution

- Easy to install and maintain

Cons:

- Cannot withstand extreme temperatures

- Less durable in heavy-load applications

- Can wear out faster compared to stainless steel in abrasive environments

Pros:

- Can handle extreme temperatures and heavy loads

- Long lifespan with proper maintenance

- High tensile strength and durability

- Suitable for harsh industrial environments

Cons:

- Expensive upfront cost

- Heavier and harder to install

- Requires maintenance to prevent rust or corrosion in some conditions

Polyester mesh belts are the best option if:

- You need a lightweight, flexible belt for curved conveyors

- Your application involves exposure to moisture or chemicals

- You are looking for a cost-effective solution

- The temperature of the working environment is moderate (below 150°C)

- You need a belt that is easy to install and replace

Industries that commonly use polyester mesh belts:

- Paper and pulp production

- Food processing (drying and washing applications)

- Textile and fabric processing

- Wastewater treatment

Stainless steel mesh belts are the better choice if:

- Your application requires heat resistance above 150°C

- You need a belt that can withstand heavy loads and mechanical stress

- Your environment involves extreme wear and tear (e.g., sharp objects, abrasive materials)

- Longevity and durability are top priorities

- You work in industries that demand strict hygiene and fire resistance

Industries that commonly use stainless steel mesh belts:

- Metallurgy and high-temperature processing

- Baking and food production requiring heat resistance

- Chemical and pharmaceutical industries

- Heavy-duty industrial applications (e.g., automotive, mining, glass manufacturing)

The choice between polyester mesh belts and stainless steel mesh belts depends on your specific industry needs. If you prioritize flexibility, moisture resistance, and affordability, polyester mesh belts are the right fit. However, if your application requires high durability, heat resistance, and strength, stainless steel mesh belts are the better option.

By evaluating your operational requirements, budget, and environmental conditions, you can select the best belt for optimal performance and efficiency. If you're unsure which belt is right for your business, consult with an expert to ensure the best decision for your application.

Do you need help choosing the right mesh belt? Contact us today for professional guidance and high-quality solutions!