Dryer fabric in papermaking serves two functions. First, it removes the remaining water in the web that cannot be removed by vacuum or pressing. Second, it causes fibres to bond together by hydrogen bonding.

On a paper machine, drying is accomplished by passing the web around a series of steam-heated cylinders, dryer fabric threaded in it to press the paper onto the hot rolls. There are about 40 to 70 dryer cylinders on a typical paper machine, and this is by far the largest part of a paper machine.

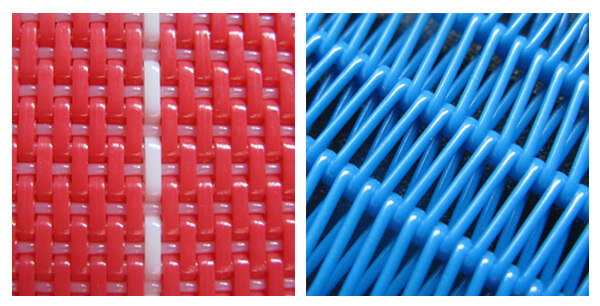

PFM Screen's dryer fabrics are mainly divided into two series: spiral dryer fabrics and woven dryer fabrics, product range covers all the dryer fabrics needed on paper and board machines. The polyester dryer fabrics are for normal paper machine conditions, whereas the PPS reinforced dryer fabrics are for hydrolysis-prone positions where high steam pressures are used.

PFM Screen's dryer fabrics are trusted by paper and board manufacturers to speed up drying rate, enhance paper quality and increase energy savings.

Features of Dryer Fabric

High contact surface area and efficient heat transfer

Good dimensional stability

Excellent wear and jam resistance

Maximal runnability

Strong warp loop seam

Flexible and strong edge reinforcement

Easiness to clean

Good heat transfer with increased ventilation

Application of Dryer Fabrics

In addition to the drying of papermaking, polyester dryer fabrics are also applied on the rotary screen printing machine in the dyeing and printing industry, coal washing machines in the coal washing industry, conveyor belts for ovens in the food processing industry, etc.