PFM Screen will solve your filter, dewatering, and drying conveyor belting challenges across applications including sewerage treatment, sludge dewatering, solid-liquid separation & drying, fruit vegetable juice pressing, dewatering manufactured parts, power plant desulphurization, and cleaning water from food and vegetable wastes, etc.

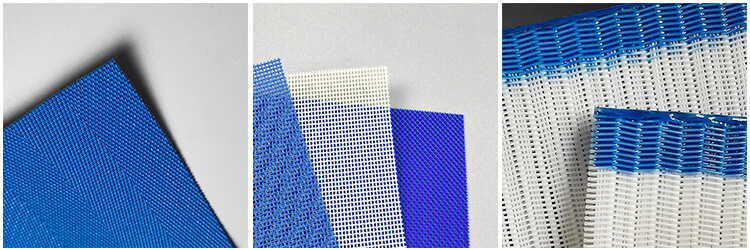

The filter or dewatering belt can choose different mesh sizes and weaving methods according to different applications. The mesh size can be as small as micrometers, which can remove the turbidity visible to the naked eye, make the muddy water clear and remove oil stains. Different weaving methods form different surface structures of the filter belt to meet your various filtration and or dehydration requirements.

All filter belts of PFM Screen have undergone high temperature treatment to ensure structural stability during work. Most of them are woven from polyester, nylon or polypropylene monofilaments, with a smooth and delicate surface and extremely high strength.

Contact PFM Screen now to discuss your needs for filter or dewatering conveyor belting for your application. We carry a full-line of filter belts.

Features of Filter Belts

A trouble-free start-up

Long lifetime, excellent fabric stability

Wear-resistant designs

Extremely strong edge treatment

Optimum drainage

Operatonal realiability

High-temperature resistance

Excellent filtration result

EU and FDA food contact regulations compliant, please contact us to get the testing report

Application of Filter Belts

Woven press filter belts for fruit & vegetable juice pressing and dewatering

Woven press filter belts for municipal sludge, industrial sludge, biologic sludge, dewatering and drying belt filter cloth for belt filter press.

Linear screen cloth for Mineral Washing, Mining Slurries Filtration and Separation

Linear screen mesh belt for Screening & Conveying in foodstuff processing & drying, fruit and vegetables washing and conveying

Spiral mesh belts widely used as filter belts, dryer screen belts or conveyor belts in dewatering processes with fibrous products, or for industry sludge dewatering and drying, nonwoven forming, and thermal applications include drying of veneers, manufacture of gypsum plasterboard or for multi-stage dryers in the foodstuff processing etc.