Reinforced Polyester Mesh Belts ( Polyester Dewatering Mesh Belts ) by PFM Screen are crafted from stable monofilament polyester fibers, woven into an open-meshed fabric that is ideal for a variety of industrial applications. These belts feature lateral and end reinforcements made exclusively from TPU or PVC belt material, ensuring compliance with food safety regulations.

Description

Reinforced Polyester Mesh Belts ( Polyester Dewatering Mesh Belts ) by PFM Screen are crafted from stable monofilament polyester fibers, woven into an open-meshed fabric that is ideal for a variety of industrial applications. These belts feature lateral and end reinforcements made exclusively from TPU or PVC belt material, ensuring compliance with food safety regulations.

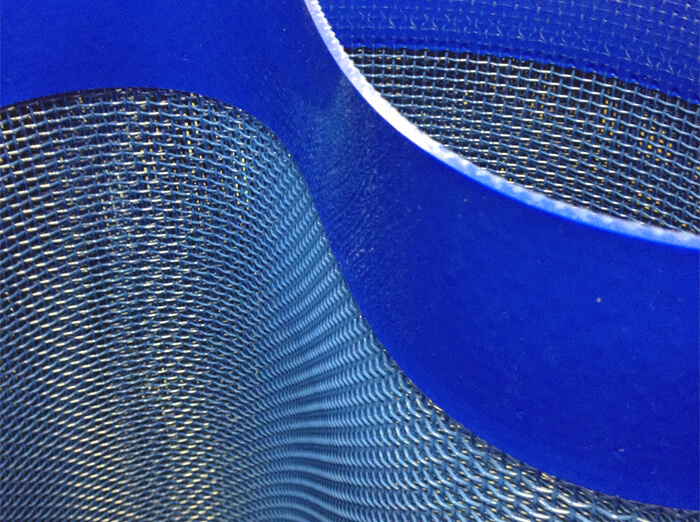

PVC edge reinforced polyester dewatering mesh belt

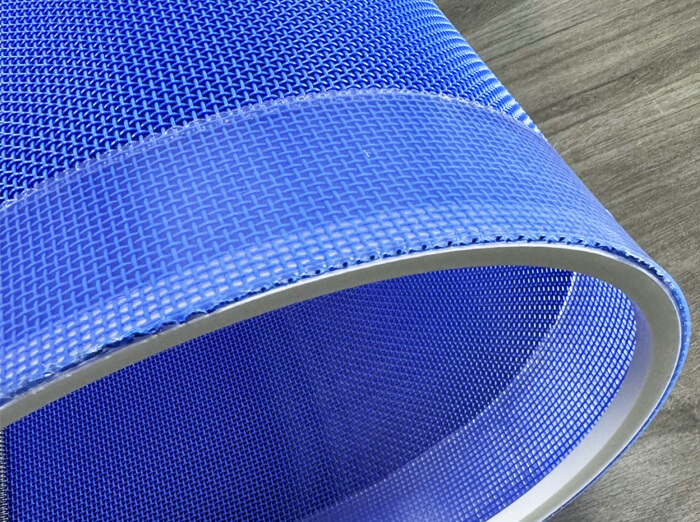

TPU edge reinforced polyester dewatering mesh belt

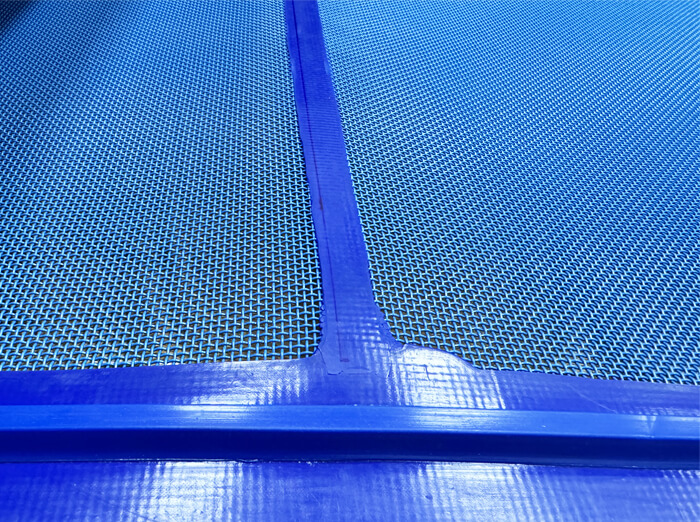

Polyester dewatering mesh belt with baffles

Polyester dewatering mesh belt with V-guides

Polyester dewatering mesh belt with weft reinforcement

By adjusting the number and diameter of the fibers, the mesh size and permeability of the fabric can be customized to meet the specific needs of different conveying applications. These filter conveyor belts are particularly suited for applications where continuous filtration, draining, and drying of the conveyed product are required.

The heat-sealed edge finishing of PFM Screen’s Reinforced Polyester Dewatering Mesh Conveyor Belts enhances their drainage capabilities, making them ideal for rinsing products directly on the belt. The sealed edges are a hygienic solution that encases the belt edges in urethane, preventing the infiltration of bacteria, moisture, oil, and other contaminants while maintaining the belt's flexibility and performance.

PFM Screen offers a variety of fabrications to tailor these belts to numerous applications. The belts are available in endless configurations or with mechanical joints and can be equipped with cleats and longitudinal tracking guides.

Feature

Reinforced Polyester Dewatering Mesh Belts Design Options:

● Edge and transverse reinforcement for increased stability and better belt control

● Various mesh sizes, manufactured to specific dimensions

● Endless splice using mechanical fasteners made of plastic or stainless steel

● Multiple guide rails and entraining elements for enhanced belt guidance

Reinforced Polyester Dewatering Mesh Belts Joining Methods:

● Single finger joining

● Stainless steel fasteners with options for flat, round, plastic threads, or hinges

Reinforced Polyester Dewatering Mesh Belts Performance Benefits:

● Great dimensional stability

● Excellent tear strength and high elongation modulus for tensile performance

● Strong splice strength

● Superior pulley friction drive and V-tracking

● FDA and EC approved for food-grade applications

● Good resistance to various chemicals, oils, and grease

● Excellent wear resistance

● Simple installation and easy to clean

Application

Reinforced Polyester Dewatering Mesh Belts Applications

● Washing and drying in fruit and vegetable processing

● Ready-to-use produce sector for vegetable washing

● Food processing industry

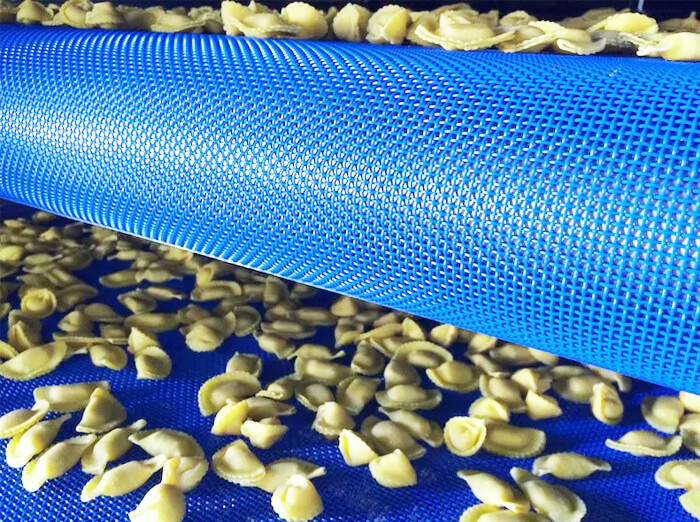

● Pasta sector for drying and pasteurization

● Drying of fruits in food processing

● Filtration processes in the dairy industry

● Transportation in the fishing industry

● Draining and washing in fish processing

● Drying and cooling processes

● Filtering and sieving of mud products

● Treating contaminated water

● Drainage processes

Polyester dewatering mesh belt for Washing and drying in fruit and vegetable processing

Polyester mesh belt for Pasta sector for drying and pasteurization

Specifications

Polyester Mesh Specifications

| Model | Wire diameter (mm) | Density (wire/centimeter) | Strength (N/cm) | weight (kg/m2) | Thickness (mm) | Mesh Radial/latitude (mm) | Aperture Radial/latitude (mm) | permeability (m3/m2/h) | CFM/127Pa | open aven | |||

| warp | weft | warp | weft | surface | joint | ||||||||

| 021002 blue | 1 | 1 | 2.85 | 2.65 | 1600 | 650 | 0.6 | 1.85 | 7.10/6.73 | 2.50/2.77 | 32000 | 2000 | 52.55 |

| 031002 blue/white | 1 | 1 | 3.2 | 3.25 | 1600 | 650 | 0.8 | 1.86 | 8.10/8.20 | 2.12/2.07 | 25600 | 1600 | 45.9 |

| 03902 | 0.9 | 0.9 | 3.9 | 3.65 | 1600 | 650 | 0.55 | 1.7 | 9.60/9.30 | 1.66/1.83 | 20000 | 1250 | 46.58 |

| 04902 | 0.9 | 0.9 | 4.65 | 4.7 | 1600 | 650 | 0.95 | 1.66 | 44542 | 1.25/1.22 | 17600 | 1170 | 33.55 |

| 04602 | 0.5 | 0.6 | 4.4 | 5.2 | 1600 | 650 | 0.58 | 1.23 | 12/13.2 | 1.72/1.32 | 19000 | 1187 | 53.32 |

| 05602 | 0.6 | 0.6 | 5.9 | 5.6 | 1600 | 650 | 0.62 | 1.1 | 14.98/14.2 | 1.09/1.18 | 18000 | 1125 | 42.89 |

| 05802 | 0.8 | 0.8 | 5.1 | 5.3 | 1600 | 650 | 0.89 | 1.48 | 13/13.5 | 1.16/1.08 | 15840 | 990 | 34.09 |

| 06652 | 0.65 | 0.65 | 7.4 | 6.8 | 1600 | 650 | 0.65 | 1.19 | 18.8/17.3 | 0.70/0.82 | 14400 | 1190 | 28.96 |

| 06802 blue/white | 0.8 | 0.8 | 6.6 | 6.5 | 1600 | 650 | 0.85 | 1.45 | 16.8/16.5 | 0.72/0.73 | 11600 | 725 | 22.65 |

| 06702 blue/white | 0.7 | 0.7 | 7 | 7 | 1600 | 650 | 0.77 | 1.3 | 17.8/17.8 | 0.72/0.72 | 11000 | 690 | 26.01 |

| 07802 | 0.8 | 0.8 | 7.8 | 7 | 1600 | 650 | 1.1 | 1.45 | 20.3/18 | 0.32/0.54 | 5920 | 370 | 16.54 |

| 09502 | 0.5 | 0.5 | 9.7 | 10.3 | 1600 | 650 | 0.5 | 0.9 | 25/26.2 | 0.53/0.47 | 10100 | 634 | 24.97 |

| 012502 | 0.5 | 0.5 | 13.5 | 8.5 | 1600 | 650 | 0.63 | 0.95 | 34.3/21.6 | 0.24/0.65 | 6500 | 6280 | 18.68 |

| 09452 | 0.45 | 0.45 | 10 | 8.6 | 1600 | 650 | 0.45 | 0.88 | 25.4/21.8 | 0.55/0.71 | 15570 | 970 | 33.71 |

| 08603 | 0.5 | 0.6 | 9.4 | 9 | 1600 | 650 | 0.6 | 0.95 | 23.8/23.1 | 0.56/0.51 | 9000 | 560 | 24.38 |

| 08502 | 0.5 | 0.5 | 9.5 | 8.6 | 1600 | 650 | 0.89 | 0.47 | 24.13/21.8 | 0.50/0.65 | 10140 | 634 | 29.93 |

| 06803 | 0.7 | 0.8 | 7 | 5.5 | 1600 | 650 | 0.75 | 1.53 | 17.8/14 | 0.72/1.0 | 16000 | 1000 | 28.56 |

| Alkali resistance PA061002 | 1 | 1 | 4.5 | 5.5 | 1600 | 650 | 0.65 | 1.63 | 17/14 | 0.35/0.60 | 5920 | 370 | 14.85 |

| 09603 | 0.5 | 0.6 | 10.5 | 9.2 | 1600 | 650 | 0.65 | 1.05 | 26.67/23.4 | 0.45/0.48 | 8300 | 518 | 44.87 |

| 07803 | 0.8 | 0.8 | 8 | 8 | 1600 | 650 | 1.15 | 1.66 | 20.3/20.3 | 0.45/0.45 | 6400 | 400 | 16.26 |

| 07903 | 0.8 | 0.9 | 7.6 | 6.5 | 1600 | 650 | 1.25 | 1.76 | 19.3/16.5 | 0.51/0.63 | 9184 | 574 | 12.96 |