We have constantly improved technology and created fabrics providing excellent runnability, high wear resistance, long-running time, good paper profiles and good retention. Specialized paper machine forming fabric designs for packaging grades continue to improve drainage.

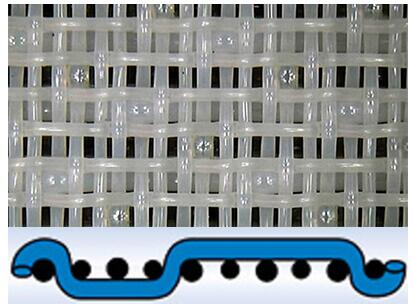

Paper Machine Clothing 1.5 Layer Forming Fabric

Traditionally, all the fabrics have direct drainage channels. In the polarized structure, the longitudinal yarns on the paper side and the roll side are displaced to form a stacked structure. This special structure eliminates the direct drainage channels traditionally used to form fabrics.

Paper Machine Clothing Triple Layer Forming Fabric

It can increase retention and help keep the machine clean. Good operability and cleanliness can reduce man-hours, thereby significantly increasing production capacity and passing Reduce the use of chemicals to save costs.

For many years, we have been studying forming fabrics. When a new polarization design was proposed, we agreed to test the new concept, although the reference list at the time was still small.

We can significantly improve the molding of Paper Machine Clothing Making Fabrics as needed, but the cleanliness and runnability are also very good with the dry content is still excellent.