The angle of the bandage is the angle between the warp of the screen, the weft line (silk) and the edge of the net frame. There are two forms of the bandage net, one is a normal bandage net, the other is a skew bandage net. The following two methods of the bandage are described respectively.

The positive bandage net is the four sides of the wire mesh meridian, the weft line parallel and perpendicular to the net frame. That is, the meridian, the weft line and the net frame are 90 degrees.

The skew bandage net refers to a certain angle on the four sides of the wire mesh, the weft line and the net frame. It is convenient to use the normal bandage net form, and it is convenient to operate. Because of the ability to make full use of silk screen, it can save the corner material of silk screen and reduce the waste of silk screen. But, in the sleeve

When using this form of screen printing plate prone to moire, so color printing is generally not used is stretching. The use of oblique cross bandage net is beneficial to improve the printing quality, and it also has some effect on increasing the amount of ink leakage. The shortage is that the silk screen is wasteful. In high precision printing and color printing, stretching angle has a direct influence on the printing quality, stretching angle is not suitable, there will be a moire. So, general copy printing, often with stretching angle is 20 degrees to 35 degrees, in the printed circuit board with high resolution, due to the use of the screen mesh is higher, so the stretching angle 45 degrees more appropriate. In the actual bandage network, in order to reduce the waste of silk screen, the general copy of print is usually used as a normal bandage.

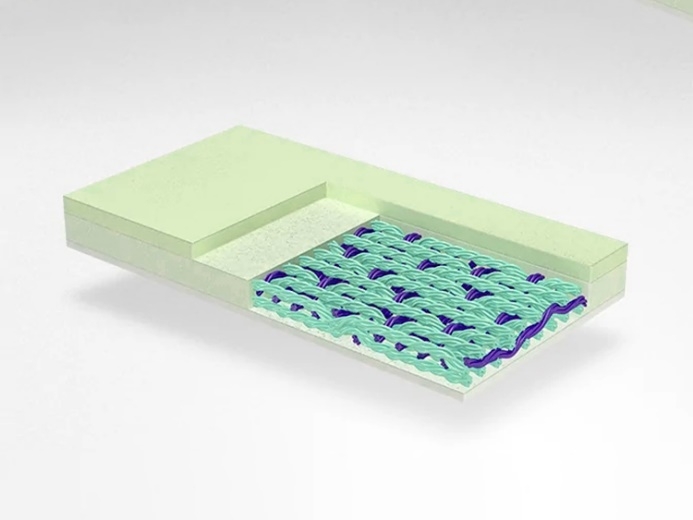

Paper Machine Clothing Double Layer BOM Press Felts

The precision of screen printing is related to the precision of screen plate, and the wire mesh tension is one of the important factors that affect the quality of screen printing plate. Material and strength, silk screen tension and net frame of the prime, temperature and humidity, stretching method and so on. Usually in the manual stretching and no tension tester under tension to determine the main experience and decide, the tension and the network side of the screen, while stretching fingers press the screen, the general finger pressure screen, feel the screen has certain elasticity can be. In the use of the bandage machine and the large net frame bandage net, the tension instrument is generally used to test the wire mesh tension.

When the net is used to stretch the net, the movement of the clamping chuck is controlled by barometer, so the pressure value of the mesh is different. Usually a stretch mesh pressure value is 7-9kg/cm2; the nylon mesh stretching pressure value is 8--10kg/cm2; polyester mesh stretch mesh pressure value is 8--10kg/cm2; stainless steel wire mesh stretching pressure value is 10--13kg/cm2.

The above is the reference value of several kinds of wire mesh when drawing the net. The net can refer to these data and draw the net according to the actual situation, so as to get an ideal tension of the net.