Filter belts is an indispensable supply for many industries. If you want to get quality filter belts products to meet your requirements at a very reasonable price, you must master some skills and methods when purchasing filter belts. Shop around to buy better products.

First, choose the filter belts material reasonably according to your own needs. Generally speaking, the filter belt material includes galvanized wire, as well as black steel wire, black iron wire and stainless steel wire. Price and performance vary among different materials. So make a reasonable choice according to your specific needs. Thus you avoid spending unnecessary money.

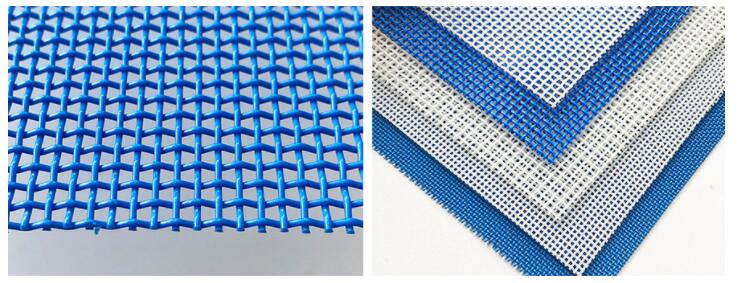

Second, choose the appropriate mesh size of the filter belts. The specifications of the filter belts are various for you to choose. So purchase filter belts products with the appropriate mesh size that fit the functions you need.

Third, the type of filter belts production process is also a very important basis for selection. In general, the production process used in filter belts mainly includes braiding, welding, punching, etching and many other types. The preparation of filter belts is mostly used for screening and filtration. While the welded filter belts is mostly used in the decoration and protection. So when choosing filter belts, you must care for the production characteristics of your own industry and the future use of the specific environment to make a reasonable judgment and selection.

1. To ensure that the filter belts on the frame plate is flat and fixed, to avoid damage to the filter belts by folding and pressure.

2. When using industrial filter belts, first of all, we should observe whether there is an identification permit from the relevant health department, and also ensure that there are no side effects on human body.

3. Filter belts will become hard after use, hydrophobicity and breathability deterioration. In order to avoid these situations, while extending the service life of the filter belts, we must remember to clean after use.

4. When making the cut, it is recommended to use a soldering iron to iron the cut.

5. The filter cake should not stick to the filter belts for too long, which will cause deformation and sagging of the filter belts.