Polyester mesh belts are essential components in the production of spunbond and meltblown nonwoven fabrics. These belts serve as the forming surface where molten polymer filaments are deposited, cooled, and bonded to create nonwoven materials widely used in hygiene products, medical textiles, filtration media, and more.

Description

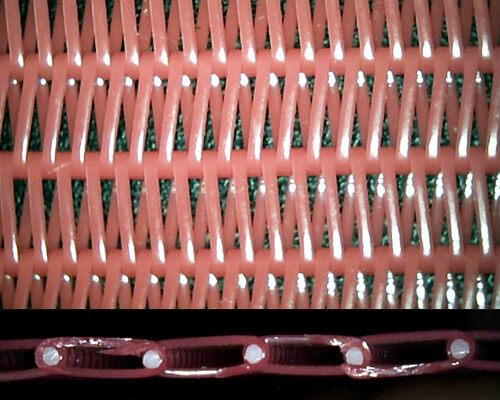

Spunbond/Meltblown Mesh Belt, also named Spunbond Nonwoven Formation Belt, Spunbond Nonwoven Forming Belt, Spunbond Spin Belt. Spunbond/Meltblown forming belts are specifically designed for use in the production of non-woven fabrics using the Spunbond/Meltblown process. These belts are an essential component of the production line and play a crucial role in ensuring the quality and consistency of the non-woven fabric. The nonwoven forming belts produced by PFM Screen offer good grip for the filaments and good release properties of the nonwoven on the forming belts at the belt ends.

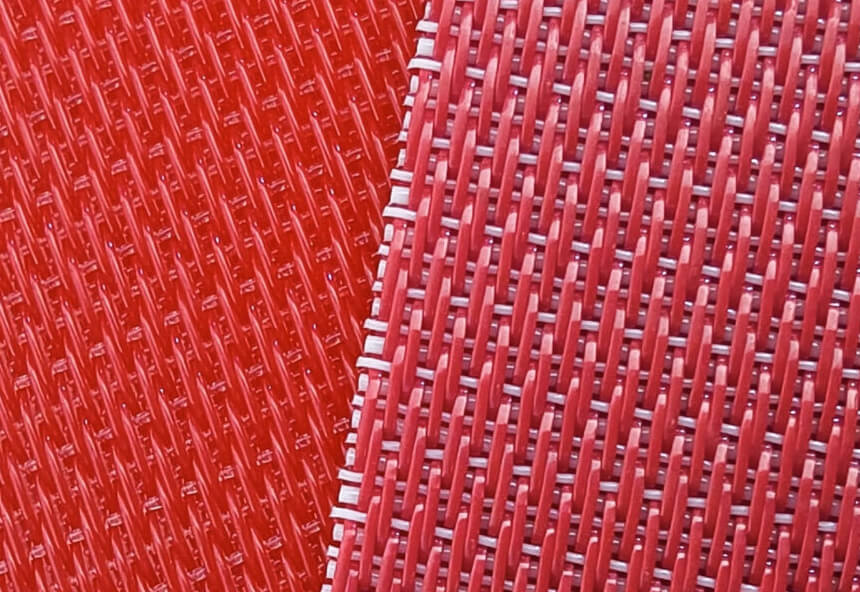

The raw material of spunbonded non-woven fabric is PE or PP, which may generate static electricity during the production process. Therefore, we have designed a series of anti-static mesh belts to solve this problem.

Antistatic Mesh Belt for Spunbond & Meltblown

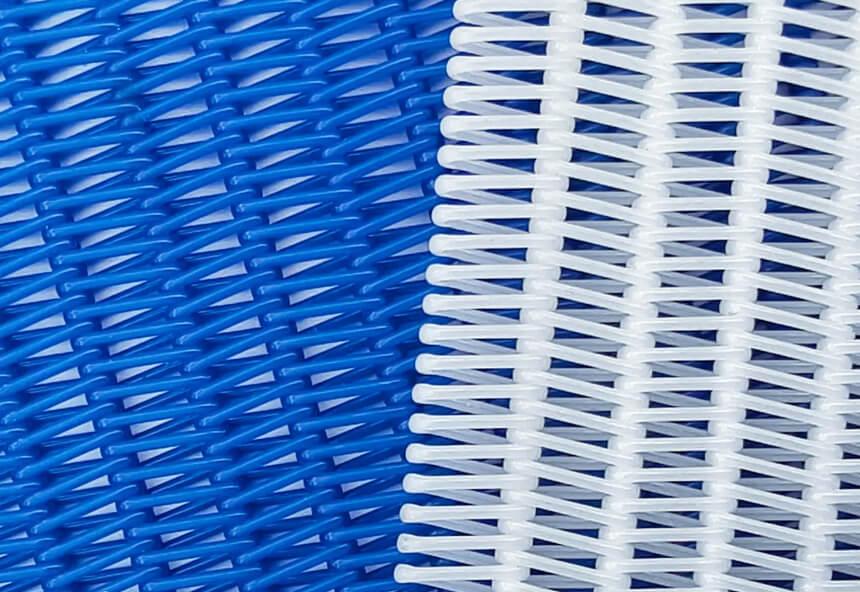

Hydrolysis Resistance Mesh Belt for Spunbond & Meltblown

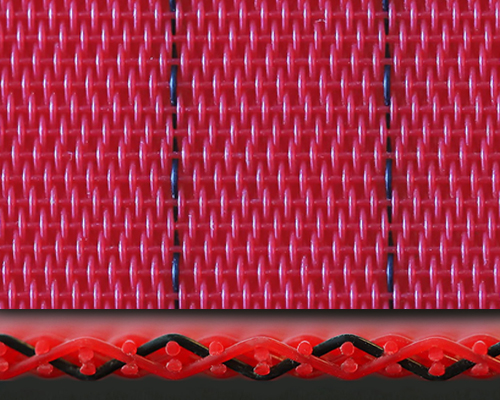

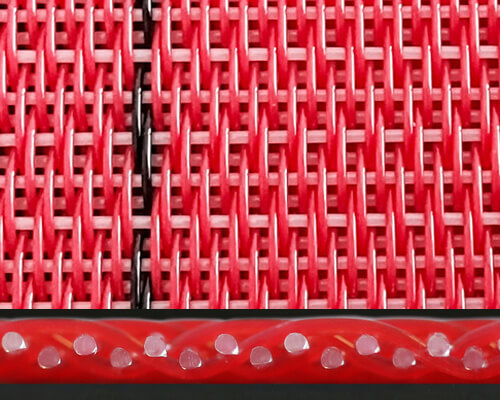

Spiral Mesh Belt for Spunbond & Meltblown

Feature

1. High Strength & Dimensional Stability: Manufactured from high-strength polyester monofilament, these belts can withstand the high temperatures and mechanical stresses involved in nonwoven fabric production, ensuring consistent fabric quality.

2. Non-Stick Surface: Designed with a non-stick surface, these belts prevent the fabric from adhering during production, facilitating smooth operation and easy release of the nonwoven fabric.

3. High Porosity & Air Permeability: The belts are engineered with high porosity, allowing efficient air and liquid flow, which is crucial for the bonding and drying processes in nonwoven fabric production.

4. Anti-Static Properties: To address static electricity issues, especially when processing polypropylene (PP) or polyethylene (PE), some mesh belts are designed with anti-static features, ensuring smooth filament deposition and preventing fiber clumping.

Antistatic Mesh Belt for Spunbond & Meltblown

Hydrolysis Resistance Mesh Belt for Spunbond & Meltblown

Spiral Mesh Belt for Spunbond & Meltblow

Application

These belts are integral to the production of nonwoven fabrics used in medical, hygiene, filtration, and automotive applications. Polyester mesh belts are utilized in various nonwoven fabric manufacturing processes, including:

Spunbond (S): Continuous filaments are spun and laid onto the belt, forming a web that is bonded to create a fabric.

Meltblown (M): Fine fibers are produced by extruding molten polymer through fine nozzles, forming a web on the belt.

Spunmelt Combinations (e.g., SS, SXS, SSS,SMS, SSMS, SMMS, SMMMS, SSMMS): Combining spunbond and meltblown processes to produce fabrics with varying properties.

Specifications

| Series | Model | Diameter ( mm ) | Density (wire/centimeter) | Air permeability (m3/m2h) | ||

| Warp | Weft | Warp | Weft | |||

| Antistatic | PFM-Spunbond-A8848 | 0.68PET+0.45Bronze | 0.8PET | 12 | 6.8 | 9887 |

| PFM-Spunbond-A8848-1 | 0.68PET+0.45Carbon | 0.8PET | 12.3 | 6.3 | 8500 | |

| PFM-Spunbond-A22504 | 0.5PET+0.52Carbon | 0.5PET | 24 | 12 | 12000 | |

| Hydrolysis Resistance | PFM-Spunbond-HRF4106 | 0.55*0.38PET | 0.6PET | 20.5 | 10.5 | 9600 |

| PFM-Spunbond-HRR4106 | 0.5PET | 0.6PET | 18.5 | 11 | 9600 | |

| PFM-Spunbond-HRF25870 | 0.40*0.60PET | 0.40*0.70PET | 21 | 13 | 10000 | |

| PFM-Spunbond-HRF25890 | 0.42*0.62PET | 0.40*0.80PET | 21 | 12 | 11000 | |

| Spiral | PFM-Spunbond-Super loop | 3.03PET | 1.64PET | 0.9 | 1.1 | 12000 |

| PFM-Spunbond-Large loop | 2.45PET | 1.4PET | 0.7 | 0.9 | 6800 | |

| PFM-Spunbond-Medium loop | 2.45PET | 1.31PET | 0.7 | 0.9 | 4000 | |

| PFM-Spunbond-Small loop | 1.87PET | 0.97PET | 0.5 | 0.8 | 1920 | |

| Custom specification is available if you can't find the suitable size. | ||||||