Press felts play an important role in removing moisture from the paper web after the forming section, while imparting smoothness and transporting it to the dryer section. To this end, press felts need to provide the following functions: water removal, smoothing and runnability. In recent years, larger and faster paper machines require press felts of higher consistency and quality.

According to the location on the paper machine can be divided into wet felts, top felt and dryer felt. The function of the wet felt is to press the raw paper to make it dehydrated and smooth the paper surface. The top felt is used above the wet felt and plays the role of leading, flattening paper and drying. Dryer felt wraps the dryer cylinder to iron and dry the paper.

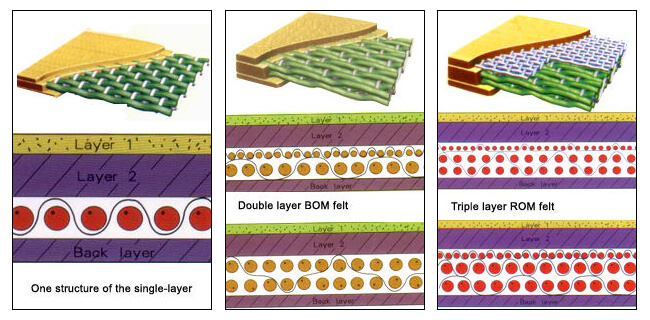

BOM Felt is composed of bottom net layer and fiber layer.The bottom mesh layer is made of monofilament, monofilament and multifilamentcomposite chemical fiber materials.The single layer, double layer, mult-layer (1 +1,1+2,2+ 2) and other organizational structures are madeby using different weaving technologies; the common synthetic fibers in the fiber layer mainly include nylon staple fiber,polyester staple fiberand other fiber raw material; the staple fibers with the same or different thickness are laid in layers on the bottom net, and then The bottommesh layer and fiber layer are processed by needling, heat setting and other special post finishing processes to make BOM felt.

Features of press felts

The dehydration rate of press felts is very high. The smooth and dense press felts surface provides high hydraulic pressure and helps good press zone dewatering. Conversely, the open back will affect the vacuum of the suction roller.

Smooth and compact press felts surface and resin impregnated (SMO), no lint at the initial stage.

Press felts are easy to maintain a clean structure; no stickiness, uneven clogging, etc. in old age.

The total energy consumption of press felts is low. High dehydration results in high dry content, low steam pressure and low cover temperature. In addition, the performance of press felts. remains unchanged during the service life of press felts, which also helps to achieve good energy consumption levels for press felts.

Advantages of press felts

The press felts are well dehydrated and have a high dry content.

press felts start quickly at maximum operating speed.

Since the characteristics of press felts remain unchanged and the felt wear is less, the running time is long.

The installation of joint press felts is safer, faster and simpler: installation time is shorter, less manpower required to replace felts, and cost savings are realized.

good energy consumption level.