Papermaking seam press felt is an indispensable dehydration equipment for the wet end and press end of modern papermaking.

Description

Seamed press felts allow customers to install the felts more safely and quickly thanks to their easy and strong seams. Overall costs are reduced because less labor is required to install the felt and there is relatively less downtime.

Seam press felts from PFM SCREEN offer excellent runnability, good water removal and strong, mark-free seam areas. PFM SCREEN can custom produce a wide range of seamed press felts, with double or triple layer monofilament structure, with easily adjustable void volume and openess to meet all customer requirements.

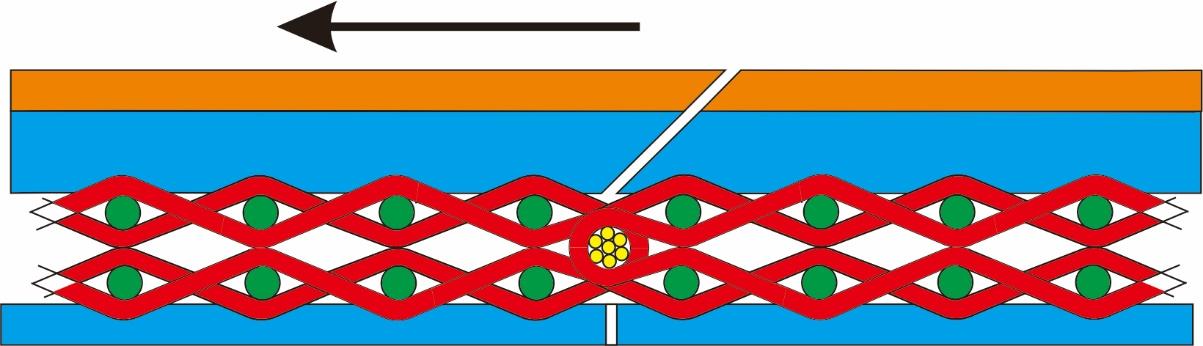

The seam unit includes two layers of warp threads and seam rings, the two layers of warp threads are woven on the weft threads respectively, at least part of the warp threads of one layer of the two layers of warp threads pass through the seam ring, and form another layer of warp threads with the warp threads of the other layer of warp threads.

The joint units are connected together by their respective joint rings, the joint rings connected by the two are arranged in sequence along the direction of the weft to form two common holes, and the two common holes are respectively inserted with core wires for joints.

Feature

Easy to seam on the machine.

Safe, easy and quick installations decrease the need of manpower and crane time, and thereby.

Increase the efficiency of the shut down time.

Durable structure with strong and non-marking seam area.

Good resistance against compaction and filling.

Good water handling capacity.

Application

PFM Screen seamed press felts have adjustable void volume and openness for all paper and board machines using virgin or recycled fiber.