PFM SCREEN’s Antistatic Polyester Dryer Mesh Belts are the ideal solution for efficient and reliable drying in the wood, biomass, and related industries.

Description

PFM SCREEN's Antistatic Polyester Dryer Mesh Belts are specially designed to cater to the demanding requirements of the wood and biomass drying industries. These belts leverage cutting-edge technology and premium materials to deliver unparalleled drying efficiency, durability, and operational reliability. Their unique design not only enhances drying performance but also minimizes energy consumption and maintenance efforts, making them an eco-friendly and cost-effective solution.

The belts are crafted from high-viscosity polyester slice wire, reinforced with interwoven bronze wires in the antistatic version to ensure permanent electrostatic discharge. This feature is particularly critical in preventing hazardous static build-up in drying environments that involve combustible materials. The belts operate effectively at low temperatures, preserving essential properties such as lignin content in wood-based products and reducing volatile organic compound (VOC) emissions.

Widely used by global equipment manufacturers, these belts offer a versatile solution for drying applications ranging from particle boards and pellets to biomass and industrial sludge. With their robust construction and precise engineering, PFM SCREEN's Antistatic Polyester Dryer Mesh Belts have become a trusted choice for industries prioritizing efficiency, safety, and sustainability.

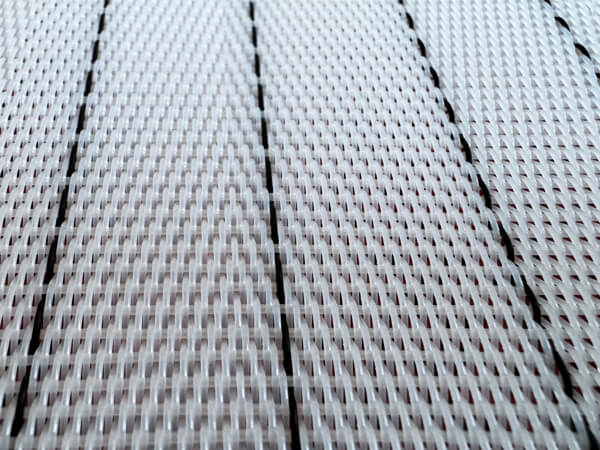

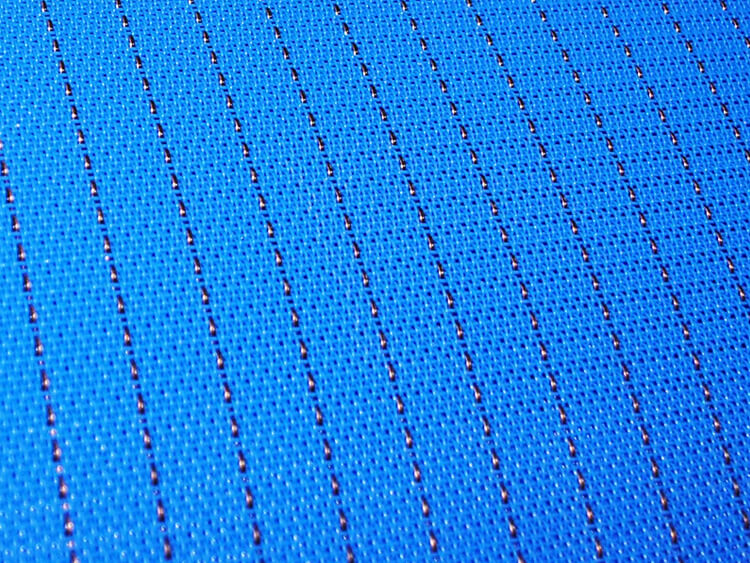

Antistatic Polyester Dryer Mesh Belts

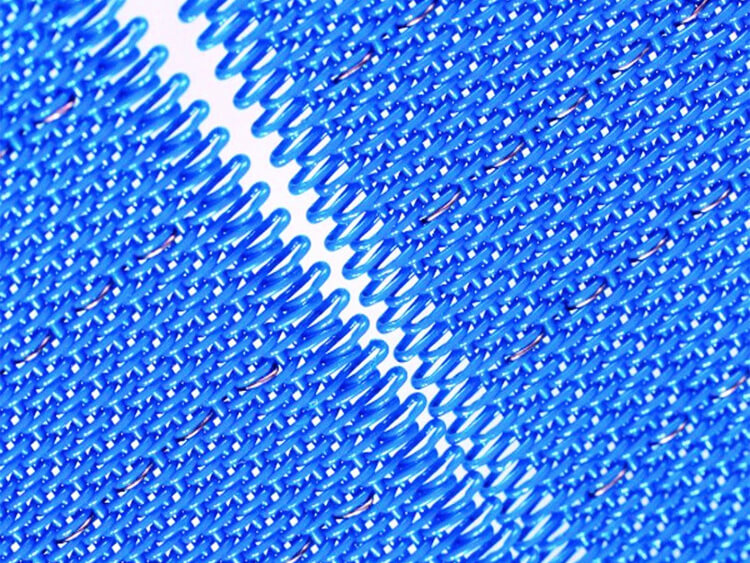

Antistatic Polyester Dryer Mesh Belts with Integrated Spiral Seam

Antistatic Polyester Dryer Mesh Belts with Spiral Seam

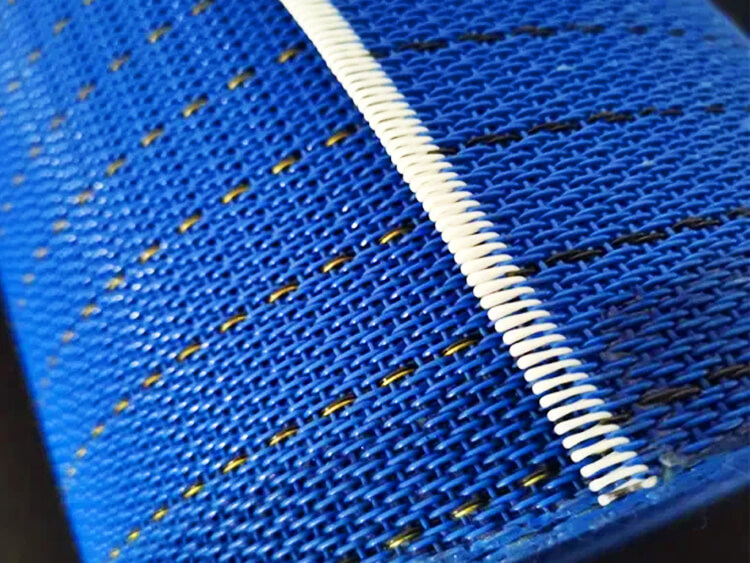

Antistatic Polyester Dryer Mesh Belts with Clipper Seam

Feature

Material Durability: Acid-resistant, alkali-resistant, wear-resistant, and capable of withstanding high temperatures up to 130°C.

Antistatic Properties: Equipped with interwoven bronze wires for permanent electrostatic discharge, compliant with ATEX standards.

Energy Efficiency: High air permeability and superior heat transfer efficiency reduce energy consumption and operational costs.

Dimensional Stability: Offers excellent form stability and flexibility for reliable performance.

Customizable Dimensions: Available in widths up to 8 meters and lengths up to 200 meters.

Environmental Compliance: Minimal VOC emissions and superior dust filtering properties contribute to eco-friendly operations.

Easy Maintenance: Designed for quick cleaning and minimal upkeep.

Application

Particle Board Industry: Drying wood for the production of particle boards or panels.

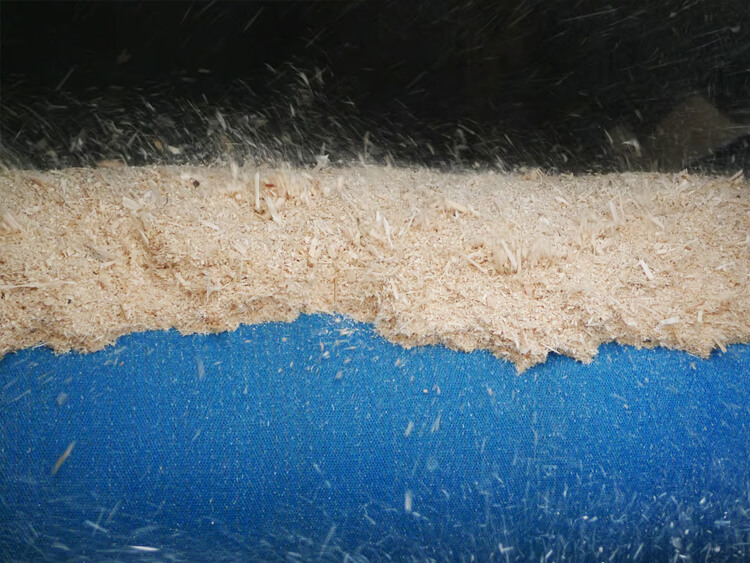

Pellet Industry: Preparing sawdust and wood shavings for pellet production.

Sugar Industry: Drying sugar beet pulp and bagasse for feed and fuel applications.

Feed Industry: Drying grass or alfalfa (lucerne) into high-quality feed.

Biomass Energy: Preparing wet biomass for combustion, pyrolysis, or pelletizing.

Renewable Energy: Ensuring optimal drying for bark, forest residue, and other biomass materials.

Antistatic Polyester Dryer Mesh Belts for Sawdust and Wood Chips Drying

Antistatic Polyester Dryer Mesh Belts for Biomass Drying

Antistatic Polyester Dryer Mesh Belts for Grass Drying

Specifications

Operating Temperature: Maximum 130°C

Maximum Dimensions:

Length: Up to 200 meters

Width: Up to 8 meters

Material Composition: High-viscosity polyester slice wire with interwoven bronze wires (Antistatic version)

Compliance: ATEX certified for safe operation

Air Permeability: High for enhanced drying efficiency

Filtering Characteristics: Excellent dust control with reduced emission