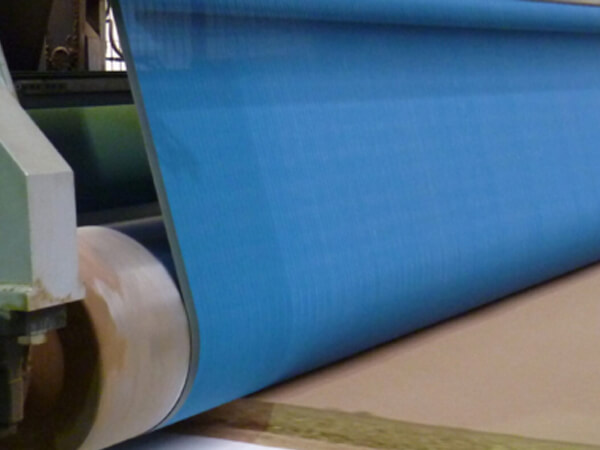

The PFM SCREEN pre-press and ventilation belts are designed for MDF and particleboard manufacturing, ensuring efficient deaeration and uniform pre-compression. With a stable structure, antistatic properties, high chemical and abrasion resistance, and quick splice options, they enhance product quality, reduce downtime, and are ideal for modern continuous pre-press systems.

Description

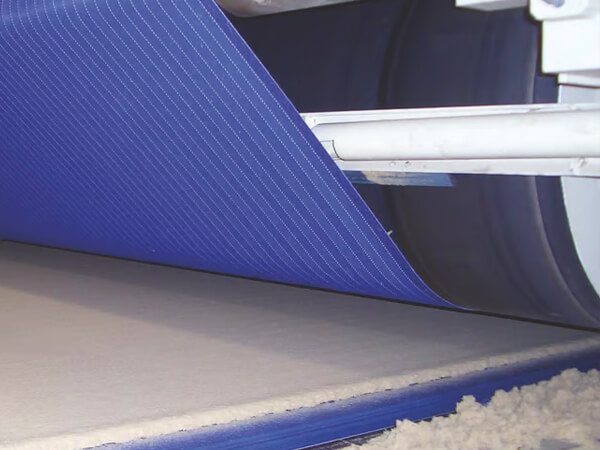

The PFM SCREEN Pre-press and Ventilation Belts are specialized solutions designed to enhance the manufacturing process of MDF (Medium-Density Fiberboard) and particleboard. These belts play a critical role during the pre-press phase by ensuring efficient ventilation and uniform pre-compression of fiber mats or chip mats.

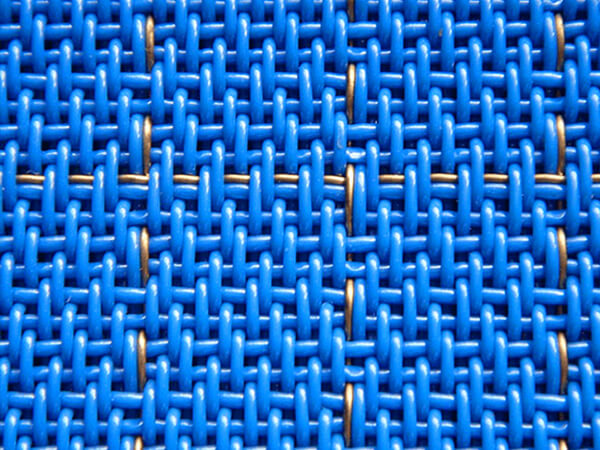

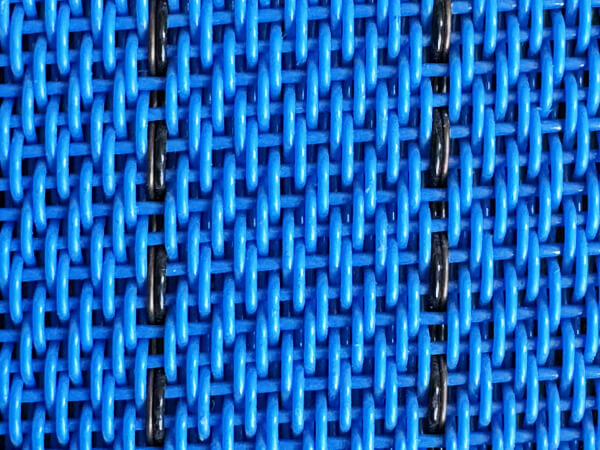

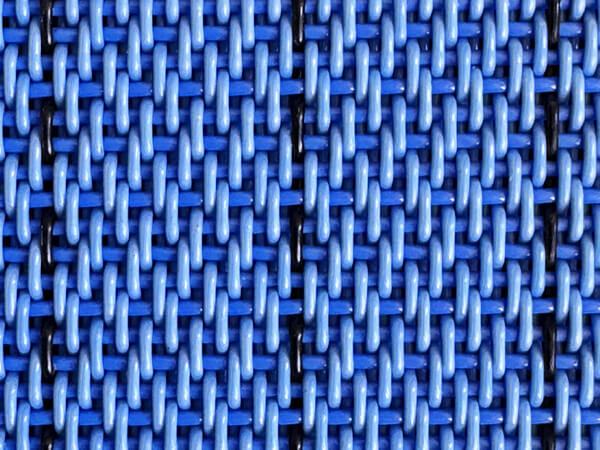

In modern production facilities, the spread fiber mat or chip mat must undergo precise deaeration to prevent air pockets that can compromise the final product's quality. The PFM SCREEN belts achieve this by expelling air effectively while avoiding lateral displacement of the wood material. Their permeable fabric structure, with mesh sizes tailored to specific wood materials, ensures an optimal balance between ventilation performance and chip geometry.

To further enhance operational safety and performance, the belts incorporate copper or carbon threads woven into the polyester yarn. This feature ensures permanent electrostatic discharge in compliance with Atex standards, eliminating risks of sparks or adhesion issues. The belts’ robust construction, featuring sealed edges and a stable fabric structure, guarantees long-lasting performance and minimal maintenance. Additionally, their compatibility with continuous pre-press systems ensures the fiber or chip mats remain compressed and stable, reducing the risk of spring-back effects before entering the main press.

PFM SCREEN ventilation belts deliver unparalleled productivity improvements through high airflow rates, robust durability, and superior chemical resistance. These features make them indispensable for manufacturers seeking to optimize production efficiency and product quality.

Feature

Stable Fabric Structure with Sealed Edges

Provides uniform ventilation and pre-compression.

Prevents lateral expulsion of material, ensuring precision and quality.

High Airflow Rate

Facilitates excellent deaeration processes.

Enhances top-layer density and increases line speed.

Reduces sanding efforts and boosts overall production quality.

Permanently Antistatic

Incorporates copper or carbon threads for electrostatic discharge as per Atex standards.

Prevents chip and fiber adhesion, ensuring smooth operations and heightened safety.

High Chemical Resistance

Resists chemical alterations, avoiding sticking and accumulation on the belt.

Requires minimal maintenance and ensures a long service life.

High Abrasion Resistance

Made from strong polyester monofilament for durability.

Delivers extended service life under demanding conditions.

Efficient Joining on Site

Offers multiple joining options: Endless Woven, Stainless Steel Fastener, Plastic Pin-seam, and Finger Splice.

Ensures fast, flexible, and strong connections with minimal production interruptions.

Application

PFM SCREEN ventilation belts are designed for use in MDF and particleboard manufacturing, specifically during the pre-press phase. These belts provide effective ventilation and pre-compression for fiber mats or chip mats, making them ideal for:

Continuous pre-press systems.

High-speed production lines.

Facilities requiring enhanced safety and reduced maintenance.

Specifications

Material: Polyester monofilament with interwoven copper or carbon threads.

Delivery Widths: Up to 8000 mm.

Airflow Rate: High and controlled for optimal deaeration.

Splice Options:

Endless Woven

Stainless Steel Fastener

Plastic Pin-seam

Finger Splice Prepared

Standards Compliance: Atex standards for electrostatic discharge.

| Model | Wire diameter (mm) | Density (wire/centimeter) | Tensile strength (N/cm) | Conductive thread | Thickness | Air permeability m3/m2h | Air permeability L/m2/S(200Pa) | |||

| Wrap | Weft | Wrap | Weft | surface | joint | |||||

| 14804K | 0.68 | 0.8 | 14.8 | 7.2 | 2000 | 900 | Copper | 1.95 | 6800 | 430 |

| 14804T | 0.68 | 0.8 | 14.8 | 7.2 | 2000 | 900 | Carbon | 1.95 | 6800 | 430 |

| 14804M | 0.68 | 0.8 | 14.8 | 7.2 | 2000 | 900 | Copper & Carbon | 1.95 | 6800 | 430 |