With their precision engineering and robust design, PFM SCREEN’s Steam Pre-heater Spiral Belts are the ultimate solution for efficient, high-quality steaming in the wood industry.

Description

PFM SCREEN’s Steam Pre-heater Spiral Belts are meticulously designed to enhance the efficiency and performance of modern wood-based production plants. These specialized belts are integral components of pre-heating units, which play a crucial role in preparing pre-pressed chip or fiber mats before they enter the continuous press. By employing advanced steam injection technology, the belts ensure uniform and effective heating, significantly reducing production times and enabling throughput improvements of 10-30%.

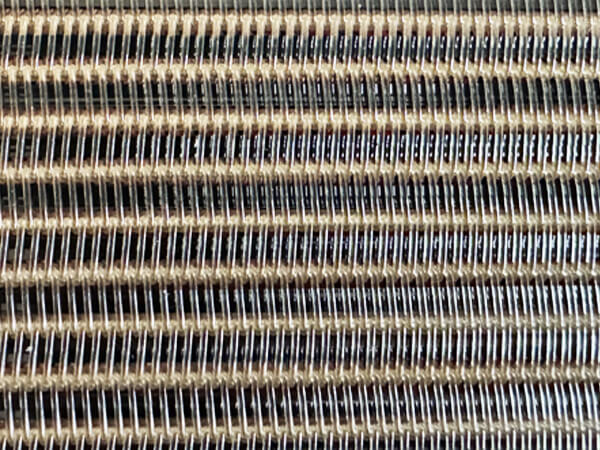

Crafted with precision and utilizing high-quality materials, PFM SCREEN’s spiral belts are tailored to meet the demanding requirements of the artificial board industry. Their robust construction ensures excellent tracking stability, while their flexible design allows them to accommodate even the tightest roller diameters. Furthermore, customizable air permeability options, achieved through specialized filler wires, make these belts adaptable to diverse customer needs. Trusted by manufacturers worldwide, PFM SCREEN’s steam pre-heater belts are synonymous with durability, consistency, and exceptional performance, making them an indispensable asset in the wood-based panel production process.

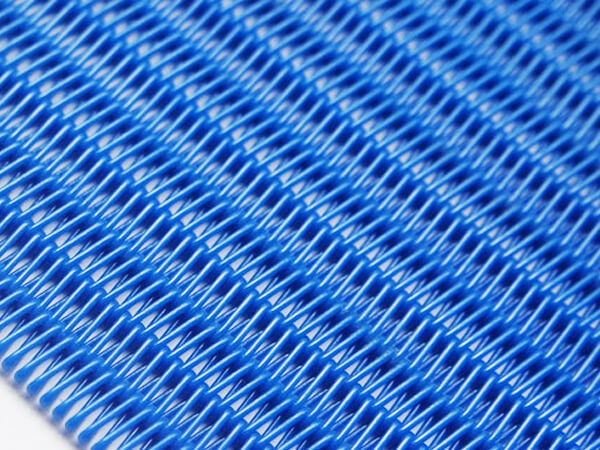

Polyester Steam Pre-heater Spiral Belts Without Filler Wires

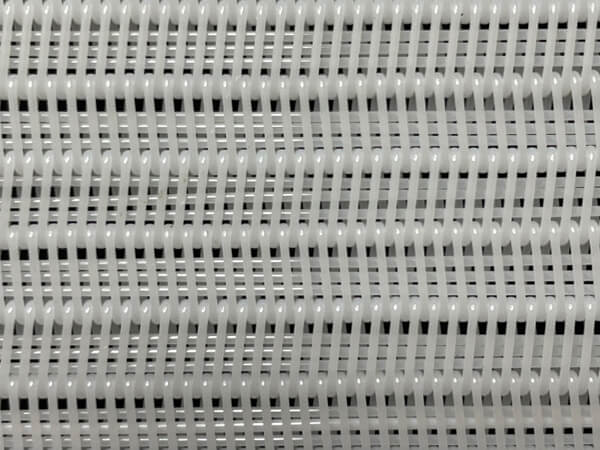

Polyester Steam Pre-heater Spiral Belts With Round Filler Wires

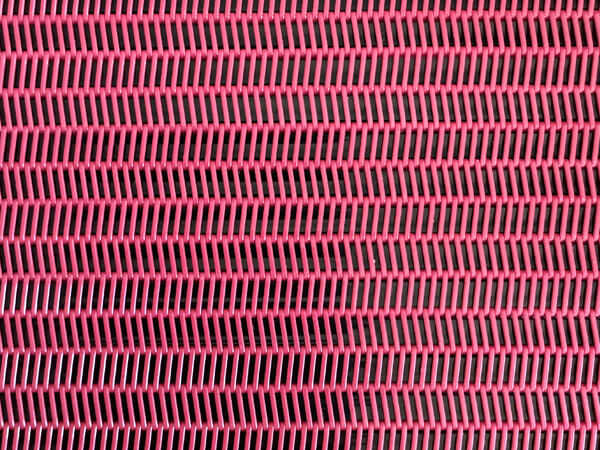

Polyester Steam Pre-heater Spiral Belts With Flat Filler Wires

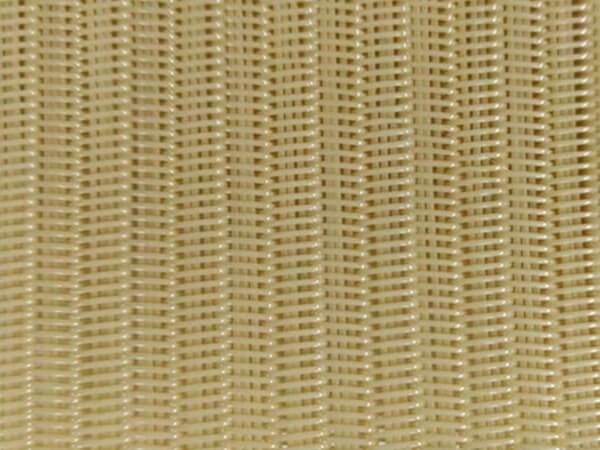

PPS Steam Pre-heater Spiral Belts With Round Filler Wires

PPS Steam Pre-heater Spiral Belts With Flat Filler Wires

Feature

Features:

Made from high-performance materials such as polyester and PPS plastic for excellent thermal resistance and hydrolysis handling.

Spiral construction with customizable filler wires for optimized air permeability and robust structure.

Available in widths up to 8 meters and endless lengths, sealed to size for enhanced stability.

Superior tracking stability and mechanical integrity for seamless operation.

Functions:

Pre-heats chip and fiber mats using steam injection, reducing production times.

Ensures uniform temperature distribution for consistent pre-heating.

Curves around tight roller diameters due to its flexible design.

Benefits:

Speeds up production processes by 10-30%, maximizing efficiency.

Delivers high throughput rates and excellent release properties.

Reduces energy costs by optimizing the heating process.

Long-lasting and easy to maintain, ensuring minimal operational disruptions.

Application

PFM SCREEN’s Steam Pre-heater Spiral Belts are widely used across various sectors of the wood-based panel industry, including:

Medium-density fiberboard (MDF) production.

High-density fiberboard (HDF) manufacturing.

Particleboard and oriented strand board (OSB) production.

Plywood and other engineered wood panel applications.

These belts are ideal for operations requiring reliable pre-heating solutions that enhance both speed and product quality.

Specifications

Material Options: Polyester, PPS plastic (for high-temperature applications)

Width: Up to 8 meters

Length: Endless, sealed to size

Operating Temperature: Up to 200°C (depending on material choice)

Air Permeability: Customizable through filler wires

Tracking Stability: Optimized for smooth and consistent operation

Durability: Designed for long-term use in demanding production environments